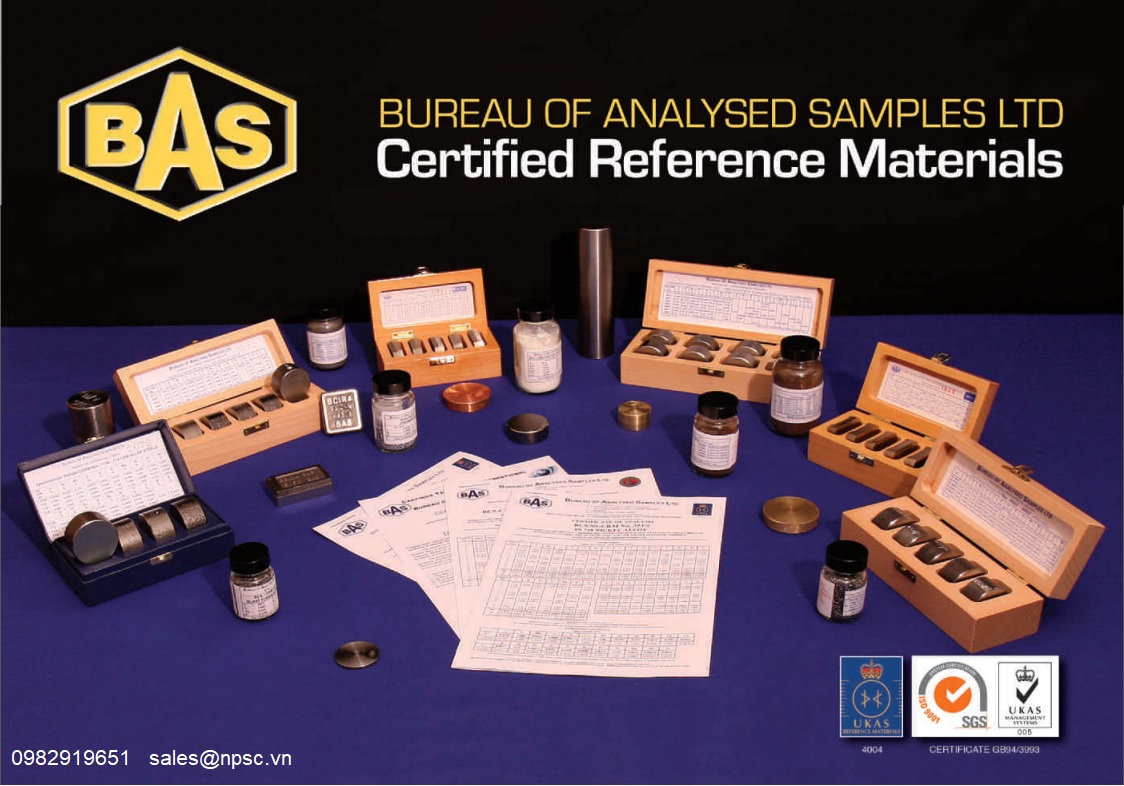

Mẫu chuẩn CRM thép và hợp kim BAS

BUREAU OF ANALYSED SAMPLES

Xuất xứ: UK

Danh mục: Hóa chất phân tích, Mẫu chuẩn đối chiếu CRM

Thẻ: CRM BAS, Mẫu chuẩn BAS, Mẫu chuẩn hợp kim BAS

BUREAU OF ANALYSED SAMPLES (BAS) là nhà sản xuất mẫu chuẩn CRM thép và hợp kim hàng đầu thế giới được thành lập năm 1935 tại Anh. Ngoài mẫu chuẩn CRM thép hợp kim BAS cũng sản xuất các gốm sứ, xi măng…

Hiện tại BAS đang phối hợp với cơ quan mẫu chuẩn của Đức VDEH / BAM và của Pháp IRSID / CTIF để sản xuất các mẫu chuẩn hợp kim cho EURONORM và ECISS (European Committee for Iron and Steel Standardization).

I. Mẫu chuẩn CRM thép và hợp kim BAS phân tích thành phần hóa học

Mẫu chuẩn CRM phân tích thành phần hóa học BCS-CRM

- BCS-CRM 111; 111/1; 112; 113, 114: Low Alloy Steel, đóng gói 100g

- BCS-CRM 115: Calcium Treated Steel, đóng gói 100g

- BCS-CRM 116: Calcium Treated Steel, đóng gói 100g

- BCS-CRM 161/4: 0.8% Carbon Steel, đóng gói 100g

- BCS-CRM 176/3; 176/4: Manganese Ore, đóng gói 100g

- BCS-CRM 177/2: Lead Base White Metal, đóng gói 100g

- BCS-CRM 178/2: Tin Base White Metal, đóng gói 100g

- BCS-CRM 179/2: High Tensile Brass, đóng gói 100g

- BCS-CRM 180/2: Copper-Nickel, đóng gói 100g

- BCS-CRM 181/3: Cu Aluminium Alloy, đóng gói 100g

- BCS-CRM 182/3: 11% Si Aluminium Alloy, đóng gói 100g

- BCS-CRM 183/4: Leaded Gunmetal, đóng gói 100g

- BCS-CRM 203/6: Low Carbon Ferro-Chromium, đóng gói 100g

- BCS-CRM 204/6: High Carbon Ferro-Chromium, đóng gói 100g

- BCS-CRM 206/3: High Si & P Cast Iron, đóng gói 100g

- BCS-CRM 207/2: Gunmetal, đóng gói 100g

- BCS-CRM 214/2: Mn – Mo Steel, đóng gói 100g

- BCS-CRM 216/3: 5% Cu Aluminium Alloy, đóng gói 100g

- BCS-CRM 219/4: Ni-Cr-Mo Steel, đóng gói 100g

- BCS-CRM 220/2: High Speed Steel, đóng gói 100g

- BCS-CRM 222/1: 3.5% Ni Steel, đóng gói 100g

- BCS-CRM 225/2: Ni-Cr-Mo Steel, đóng gói 100g

- BCS-CRM 231/5; 231/6: Ferro-Molybdenum, đóng gói 100g

- BCS-CRM 232/2: 0.1% Sulphur Steel, đóng gói 100g

- BCS-CRM 236/3: Hematite Iron, đóng gói 100g

- BCS-CRM 237/2: 0.1% Carbon Steel, đóng gói 100g

- BCS-CRM 238/2: 0.2% Carbon Steel, đóng gói 100g

- BCS-CRM 241/2: High Speed Steel, đóng gói 100g

- BCS-CRM 242/2: Ferro-Tungsten, đóng gói 100g

- BCS-CRM 262/1: 10% Mg Aluminium Alloy, đóng gói 100g

- BCS-CRM 263/2: 5% Mg Aluminium Alloy, đóng gói 100g

- BCS-CRM 268/1: 5% Si Aluminium Alloy, đóng gói 100g

- BCS-CRM 270: 0.09% Phosphorus Steel, đóng gói 100g

- BCS-CRM 290/2: 13% Manganese Steel, đóng gói 100g

- BCS-CRM 300/1: 6% Zn Aluminium Alloy, đóng gói 100g

- BCS-CRM 301/1: Lincolnshire Iron Ore, đóng gói 100g

- BCS-CRM 304/1: Copper Aluminium, đóng gói 100g

- BCS-CRM 307: Ce-Zn-Zr Magnesium Alloy, đóng gói 100g

- BCS-CRM 308/1: Chrome Ore, đóng gói 100g

- BCS-CRM 309: Sillimanite, đóng gói 100g

- BCS-CRM 310/1: Nimonic 90, đóng gói 100g

- BCS-CRM 313/2: High Purity Silica, đóng gói 100g

- BCS-CRM 316: 8% Al Magnesium Alloy, đóng gói 100g

- BCS-CRM 317: Low C High Si Steel, đóng gói 100g

- BCS-CRM 318A: 0.01% Oxygen Steel (6.35mm dia. x 95 mm rods), Đóng gói cặp

- BCS-CRM 318B: 0.01% Oxygen Steel (12.7mm dia. x 127mm rods), Đóng gói / dây

- BCS-CRM 319/1: Magnesia, đóng gói 100g

- BCS-CRM 332: Aaustenitic Stainless Steel, đóng gói 100g

- BCS-CRM 339; 340; 341; 342: Ferritic Stainless Steel, đóng gói 100g

- BCS-CRM 343: Wrought Aluminium Alloy, đóng gói 100g

- BCS-CRM 344: 70/30 Brass, đóng gói 100g

- BCS-CRM 345, 346: Nickel Alloy IN 100, đóng gói 100g

- BCS-CRM 347: Electronic Flowsolder, đóng gói 100g

- BCS-CRM 348: Ball Clay, đóng gói 100g

- BCS-CRM 349: 3.5% Cu Aluminium Alloy, đóng gói 100g

- BCS-CRM 350: Nickel Alloy IN 713, đóng gói 100g

- BCS-CRM 351/1: Nickel Alloy IN 718, đóng gói 100g

- BCS-CRM 353: Sulphate Resisting Portland Cement, đóng gói 100g

- BCS-CRM 354: White Portland Cement, đóng gói 100g

- BCS-CRM 355: Tin Ore, đóng gói 100g

- BCS-CRM 356, 357: Titanium Alloy, đóng gói 50g

- BCS-CRM 358: Zirconia, đóng gói 100g

- BCS-CRM 359: Nitrogen Bearing Silicon Carbide, đóng gói 100g

- BCS-CRM 360: Sialon Bonded Silicon Carbide, đóng gói 100g

- BCS-CRM 361: Chromium Metal, đóng gói 100g

- BCS-CRM 362: Mine Tailings Sample, đóng gói 100g

- BCS-CRM 363/1: Monel Alloy, đóng gói 100g

- BCS-CRM 364: Leaded Bronze, đóng gói 100g

- BCS-CRM 369; 370: Magnesite Chrome, đóng gói 100g

- BCS-CRM 371: Commercial Nickel, đóng gói 100g

- BCS-CRM 374: Phosphor Bronze, đóng gói 100g

- BCS-CRM 375/1: Soda Feldspar, đóng gói 100g

- BCS-CRM 376/1: Potash Feldspar, đóng gói 100g

- BCS-CRM 377/6: Iron Ore Sinter, đóng gói 100g

- BCS-CRM 380/1: 2% Si Aluminium Alloy, đóng gói 100g

- BCS-CRM 381: Basic Slag, đóng gói 100g

- BCS-CRM 383: Alcomax III, đóng gói 100g

- BCS-CRM 385: Leaded Brass, đóng gói 100g

- BCS-CRM 387/1: Nimonic 901 Alloy, đóng gói 100g

- BCS-CRM 388: Zircon, đóng gói 100g

- BCS-CRM 389/1: High Purity Magnesia, đóng gói 100g

- BCS-CRM 390: High Tensile Brass, đóng gói 100g

- BCS-CRM 392: Fluorspar, đóng gói 100g

- BCS-CRM 393: Limestone, đóng gói 100g

- BCS-CRM 394/1: Calcined Bauxite, đóng gói 100g

- BCS-CRM 395: Bauxite, đóng gói 100g

- BCS-CRM 396: Low Silica Magnesite Chrome, đóng gói 100g

- BCS-CRM 398: Alnico H C, đóng gói 100g

- BCS-CRM 399: Phosphorus Deoxidised Copper, đóng gói 100g

- BCS-CRM 405; 408; 404/1; 405/1: Low Alloy Steels, đóng gói 100g

- BCS-CRM 407/1 – 409/1: Low Alloy Steels, đóng gói 100g

- BCS-CRM 401/2 – 405/2: Low Alloy Steels, đóng gói 100g

- BCS-CRM 407/2; 409/2: Low Alloy Steels, đóng gói 100g

- BCS-CRM 421 – 424: Low Tungsten Steels, đóng gói 100g

- BCS-CRM 431/2 – 435/2: Plain Carbon Steels, đóng gói 100g

- BCS-CRM 452/1: Carbon Steels Residual Series , đóng gói 100g

- BCS-CRM 453/1: Carbon Steels Residual Series , đóng gói 100g

- BCS-CRM 456/2 – 460/2: Carbon Steels Residual Series , đóng gói 100g

- BCS-CRM 463: Residual Series Austenitic Stainless Steel, đóng gói 100g

- BCS-CRM 461/1 – 468/1: Austenitic Stainless Steels, đóng gói 100g

- BCS-CRM 469 – 473: Ferritic Stainless Steels, đóng gói 100g

- BCS-CRM 474; 475; 476; 479: Stainless Steels, đóng gói 100g

- BCS-CRM 481 – 484: High Speed Steels, đóng gói 100g

- BCS-CRM 491; 494; 495; 495/1: High Manganese Steels, đóng gói 100g

- BCS-CRM 505: Aluminium-Silicon Alloy, đóng gói 100g

- BCS-CRM 512: Dolomite, đóng gói 100g

- BCS-CRM 513: Limestone, đóng gói 100g

- BCS-CRM 514: Copper Concentrate, đóng gói 100g

- BCS-CRM 516: Standard Glass Sand, đóng gói 100g

- BCS-CRM 517: Brazilian Iron Ore, đóng gói 100g

- BCS-CRM 520: Zinc Concentrate, đóng gói 100g

- BCS-CRM 525: Low Iron Float Glass, đóng gói 25g

- BCS-CRM 526: Soda Ash, đóng gói 100g

- BCS-CRM 527: Blast Furnace Iron, đóng gói 100g

- BCS-CRM 528: Standard Glass Sand, đóng gói 100g

- BCS-CRM 529: Anorthic Feldspar, đóng gói 100g

- BCS-CRM 531: Low Iron Sand, đóng gói 100g

- BCS-CRM 532: Swedish Feldspar , đóng gói 100g

Mẫu chuẩn CRM phân tích thành phần hóa học ECRM

- ECRM †055-2(C) : 0.5% Carbon Steel

- ECRM †056-2(C) : 0.8% Carbon Steel

- ECRM †057-2(C) : 0.05% Carbon Steel

- ECRM †058-2(C) : 0.15% Sulphur steel

- ECRM †059-2(C) : 0.7% Carbon steel

- ECRM 064-1(C) : Nb/Ti Interstitial Free Steel

- ECRM †084-1(C) : 0.4% Carbon Steel

- ECRM †085-1(C) : 0.3% Sulphur Steel

- ECRM †086-1(C) : 0.3% Carbon Steel

- ECRM †087-1(C) : 0.15% Carbon Steel

- ECRM 088-2 : High Purity Iron

- ECRM †090-1© : 1% Carbon Steel

- ECRM 091-1 : 0.5% Carbon Steel

- ECRM 096-2(C) : Low S, Ca-Treated Steel

- ECRM †097-1(C) : High Purity Iron

- ECRM †097-2(C) : High Purity Iron

- ECRM †186-1(C) : Silico Manganese Steel

- ECRM †195-1(C) : Cr-Mo-Ni Steel

- ECRM †272-1(C) : 12% Chromium Steel

- ECRM †276-2(C) : 5% Cr-Mo-V Steel

- ECRM 281-1 : 18/9 Stainless Steel + Ti

- ECRM †285-2(C) : Maraging Steel

- ECRM †287-1(C) : High Boron Stainless Steel

- ECRM †292-1(C) : Nb – Stabilised Stainless Steel

- ECRM †295-1(C) : 4% Mo-Cr-Ni Steel

- ECRM †296-1(C) : Jethete Steel

- ECRM 376-1 : 24% Co Magnet Alloy

- ECRM 451-2 : Austenitic Cast Iron

- ECRM 481-1 : Nodular Iron

- ECRM 482-2 : Low Alloy Cast Iron

- ECRM 484-1 : Whiteheart Malleable Iron

- ECRM 486-1 : Foundry Iron

- ECRM 489-1 : White Cast Iron

- ECRM 576-1 : Ferro-Niobium

- ECRM 577-1 : Ferro-Vanadium

- ECRM 578-1 : Ferro-Molybdenum

- ECRM 579-1 : Ferro-Niobium

- ECRM 580-1 : Ferro-Chromium

- ECRM 583-1 : Ferro-Manganese

- ECRM 584-1 : Ferro-Titanium

- ECRM 587-1 : Ferro-Boron

- ECRM 590-1 : Ferro-Tungsten

- ECRM 676-1 : Iron Ore Sinter

- ECRM 682-2 : Iron Ore

- ECRM 690-1 : Haematite Iron Ore

- ECRM 776-1 : Firebrick

- ECRM 781-1 : Silicon Carbide Refractory

- ECRM 782-1 : Dolomite

- ECRM 783-1 : Tungsten Carbide

- ECRM 879-1 : Basic Slag

- ECRM 884-1 : Furnace Dust

II. Mẫu chuẩn CRM quang phổ

Mẫu chuẩn CRM quang phổ ECRM

- ECRM 055–2 (D) : 0.5% Carbon Steel ( 38 x 25 or 30 mm)

- ECRM 056–2 (D) : 0.8%Carbon Steel ( 44 x 25 or 30 mm)

- ECRM 057–2 (D) : 0.05%Carbon Stee ( 38 x 25 or 30 mm)

- ECRM 058–2 (D) : 0.15% Sulphur Steel ( 38 x 25 or 30 mm)

- ECRM 059–2 (D) : 0.7% Carbon Steel ( 38 x 25 or 30 mm)

- ECRM 064–2 (D) : Nb/Ti Interstitial Free Steel ( 38 x 25 or 30 mm)

- ECRM 084–1 (D) : 0.4% Carbon Steel ( 38 x 25 or 30 mm)

- ECRM 085–1 (D) : 0.3% Sulphur Steel ( 38 x 25 or 30 mm)

- ECRM 086–1 (D) : 0.3% Carbon Steel ( 38 x 25 or 30 mm)

- ECRM 087–1 (D) : 0.15% Carbon Steel ( 38 x 25 or 30 mm)

- ECRM 090–1 (D) : 1%Carbon Steel ( 38 x 25 or 30 mm)

- ECRM 097–1 (D) : High Purity Iron ( 38 x 25 or 30 mm)

- ECRM 097–2 (D) : High Purity Iron ( 38 x 25 or 30 mm)

- ECRM 186–1 (D) : Silico Manganese Steel ( 38 x 25 or 30 mm)

- ECRM 195–1 (D) : Cr-Mo-Ni Steel ( 38 x 25 or 30 mm)

- ECRM 272–1 (D) : 12% Chromium Steel ( 38 x 25 or 30 mm)

- ECRM 276–2 (D) : 5% Cr-Mo-V Steel ( 38 x 25 or 30 mm)

- ECRM 285–2 (D) : Maraging Steel ( 38 x 25 or 30 mm)

- ECRM 287–1 (D) : High Boron Stainless Steel ( 38 x 25 or 30 mm)

- ECRM 292–1 (D) : Nb – Stabilized Stainless Steel ( 38 x 25 or 30 mm)

- ECRM 295–1 (D) : 4% Mo-Cr-Ni Steel ( 38 x 25 or 30 mm)

- ECRM 296–1 (D) : Jethete Steel ( 38 x 25 or 30 mm)

Mẫu chuẩn CRM quang phổ SS-CRM và SCRM:

- SS-CRM 53,55,56 : Carbon Steels–Residual Series ( 38 x 12 mm)

- SS-CRM 70 : Ferritic Stainless Steel ( 44 x 13 mm)

- SS-CRM 111/1 – 114 : Low Alloy Steels ( 44 x 19 mm)

- SS-CRM 115 – 116 : Calcium Treated Steels ( 44 x 19 mm)

- SS-CRM 219/4,222/1,225/2 : Low Alloy Steels ( 38 x 19 mm)

- SS-CRM 345 : Nickel Alloy IN 100 ( 35 x 13 mm)

- SS-CRM 346A : Nickel Alloy IN 100 ( 35 x 13 mm)

- SS-CRM 350 : Nickel Alloy IN 713 ( 50 x 13 mm)

- SS-CRM 351,351/1 : Nickel Alloy IN 718 ( 41 x 13 mm)

- SS-CRM 363/1 : Monel Alloy 400 ( 38 x 19 mm)

- SS-CRM 387/1 : Nimonic 901 Alloy ( 41 x 13 mm)

- SS-CRM 401/2 – 405/2 : Low Alloy Steels (Group A) ( 38 x 19 mm)

- SS-CRM 407/2 : Low Alloy Steel (Group B) ( 38 x 19 mm)

- SS-CRM 421 – 424 : Low Tungsten Steels ( 38 x 19 mm)

- SS-CRM 432/1 – 435/1 : Plain Carbon Steels ( 38 x 19 mm)

- SS-CRM 431/2 – 435/2 : Plain Carbon Steels ( 38 x 19 mm)

- SS-CRM 456/2 – 460/2 : Carbon Steels–Residual Series ( 38 x 19 mm)

- SS-CRM 462 : Austenitic Stainless Steel ( 38 x 19 mm)

- SS-CRM 461/1 – 468/1 : Austenitic Stainless Steels ( 38 x 19 mm)

- SS-CRM 469 – 473 : Ferritic Stainless Steels ( 38 x 19 mm)

- SS-CRM 475,476,479 : Stainless Steels ( 38 x 19 mm)

- SS-CRM 482/1 – 483/1 : High Speed Tool Steels ( 38 x 19 mm)

- SS-CRMs 485/1 – 487/1 : High Speed Tool Steels ( 38 x 19 mm)

- SS-CRM 601/2 – 605/2 : Plain Carbon Cast Steels ( 44 x 19 mm)

- SS-CRM 615/1 : Low Alloy Cast Steel ( 44 x 12 mm)

- ECRM 097–1 (D) : High Purity Iron (thin disc for carbon) ( 38 x 3 mm)

- SS-CRMs 492/3, 493/3 : High Manganese Steels (Cast) ( 48 x 42 x 12 mm)

- SCRM 652/4,655/4 : Malleable Irons ( 48 x 42 x 12 mm)

- SCRM 656/9 – 660/10 : Low Phosphorus Engineering Irons ( 48 x 42 x 12 mm)

- SCRM 661/4,662/4, 665/4 : High Phosphorus Engineering Irons ( 48 x 42 x 12 mm)

- SCRM 666/12 – 670/20 : Ductile (Nodular) Irons ( 48 x 42 x 12 mm)

- SCRM 671/1 – 674/1 : Blast Furnace Irons ( 48 x 42 x 12 mm)

- SCRM 675 : Blast Furnace Iron ( 40 x 37 x 10 mm)

Mẫu chuẩn CRM quang phổ LARM, CRRM, NCRM, NIRM, SIM0, CURM:

- LARM 1 – 4 : Low Alloy Cast Irons ( 40 x 37 x 12 mm)

- LARM 5/1 : Low Alloy Cast Iron ( 48 x 42 x 10 mm)

- CRRM1/1 – 2/1 : High Chromium Irons ( 40 x 37 x 12 mm)

- CRRM3/2 – 5/2 : High Chromium Irons ( 48 x 42 x 10 mm)

- NCRM 1 – 5 : Nickel Chromium Irons ( 40 x 37 x 10 mm)

- NIRM 1,3,4,7 : Austenitic (Ni-Resist) Irons ( 40 x 37 x 12 mm)

- NIRM 2/1,5/1,6/1,8/2 : Austenitic (Ni-Resist) Irons ( 48 x 42 x 12 mm)

- SIM0 1/4, SIM0 2/3 : Silicon Molybdenum Irons ( 48 x 42 x 12 mm)

- CURM 09.01-4 to 09.03-4 : Phosphorus Deoxidised Coppers ( 50 diameter x 12 mm)

- CURM 30.04-4 to 30.21-4 : Main Elements in Brasses ( 50 diameter x 12 mm)

- CURM H30.24 : Main Elements in Brass ( 35 diameter x 12 mm)

- CURM 42.21-2 to 42.25-2 : Admiralty & Naval Brasses ( 50 diameter x 12 mm)

- CURM 43.01-4 or 43.02-4 : Aluminium Brasses ( 50 diameter x 12 mm)

- CURM 48.01-1 to 48.05-1 : Cartridge Brasses ( 50 diameter x 12 mm)

- CURM 50.01-5 to 50.04-4 : Leaded Bronzes ( 50 diameter x 12 mm)

- CURM 51.11-4 to 51.14-4 : Aluminium Bronzes ( 50 diameter x 12 mm)

- CURM 52.52-5 or 52.54-4 : Aluminium Bronzes ( 50 diameter x 12 mm)

- CURM 54.01-4 to 54.02-4 : Phosphor Bronzes ( 50 diameter x 12 mm)

- CURM 62.12-4 : Cupro-Nickel ( 50 diameter x 12 mm)

- CURM 71.31-5 to 71.33-8 : Leaded Gunmetals ( 50 diameter x 20 mm)

- PBRM L21.01-2 to L21.04-2 : Battery Alloys ( 50 x 50 x 20 mm)

III. Mẫu chuẩn CRM kiểm soát độ trôi (Setting-up Samples SUS)

Mẫu chuẩn CRM kiểm soát độ trôi SUS cho thép

- SUS A/11: Low Carbon Steel ( 44 x 25, 75 or 150 mm)

- SUS D/11: Low Alloy Steel ( 44 x 25, 75 or 150 mm)

- SUS F/6: Duplex Stainless Steel ( 44 x 25, 75 or 150 mm)

- SUS G/8: Stainless Steel ( 47 x 25, 75 or 150 mm)

Mẫu chuẩn CRM kiểm soát độ trôi SUS cho gang:

- SUS 1/19: Low Phosphorus Iron (60 x 35 x 18 mm)

- SUS 2/48: Medium Phosphorus Iron ( 60 x 35 x 18 mm)

- SUS 3/21: High Phosphorus Iron ( 60 x 35 x 18 mm)

- SUS 4/28: Ductile (Nodular) Iron ( 60 x 35 x 18 mm)

- SUS 5/56: Ductile (Nodular) Iron ( 60 x 35 x 18 mm)

- SUS 6/6: Malleable Iron ( 60 x 35 x 18 mm)

- SUS 7/8: Malleable Iron ( 60 x 35 x 18 mm)

Mua mẫu chuẩn CRM thép và hợp kim BAS tại Hà nội và TP.HCM

CÔNG TY TNHH KHOA HỌC KỸ THUẬT NAM PHONG

Tel: (024) 322 020 66 (3 lines) Fax: (024) 322 02 065

Hotline: 0982 919 651 / Email: sales@npsc.vn

Sản phẩm tương tự

-5%

Được xếp hạng 5 5 sao

Được xếp hạng 5 5 sao

Đánh giá

Chưa có đánh giá nào.